Making handmade carpets traditionally

Without a doubt, handmade oriental carpets are the most valuable. Below we will discuss the techniques of knotting oriental carpets and the different tools used to make them.

The loom used to make an oriental carpet

The looms used to knot a carpet are not complicated structures and their construction has changed little over the centuries. The simplest and probably one of the most ancient forms is the horizontal loom, which is still widely used today by various nomadic tribes and in some settlements, by newly settled nomads. The principle is simple and requires a minimum amount of material. Two pieces of logs are taken and placed parallel to each other on the ground. The most commonly used type of wood is poplar, which is a fairly common tree in carpet weaving regions and typically has a straight trunk. The warp yarns used for weaving are stretched tightly between the beams, which are secured by stakes driven into the ground. The beams, fixed by stakes, hold the warp threads taut. The weaver works kneeling or crouching and is able to remain in this position for long periods.

The weaving of the weft yarn is accelerated by means of two rods. The equivalent of this is also found on the vertical loom. With the help of one of the rods, every second warp is arranged in two planes. After the cross yarn has been inserted, the alternative warp yarns are lifted with the other rod. The horizontal loom rod is located above the loom and is held on either side by a pile of twigwood or stones. In some regions, the weft is wound over the weft rod, which is nothing more than an elongated stick that can be simply slipped between the two flat warp threads from one side of the loom to the other. The advantage of the horizontal loom is simplicity, economy and portability. The latter is particularly important for nomadic weavers, as a more complicated loom is too heavy. A further disadvantage is that it requires a lot of space, which can be a problem especially in areas where the weather prevents weaving in the open air. In such cases, the size of the loom is dictated by the space available in the dwelling. Large carpets are very difficult to make on a horizontal loom, although excellent large carpets have been made with this rudimentary device. In a carpet museum in Iran, for example, you can see a huge Tekke carpet, woven some twenty metres wide, also on a horizontal loom. Another variation of the horizontal loom, it has fixed side bars forming a frame, which hold the weaving tight even when the loom is moved. This fully framed horizontal loom, however, is used only for the production of small carpets. It is well known that many great works of art were made on just such a primitive mechanism.

Different tools used to make oriental carpets

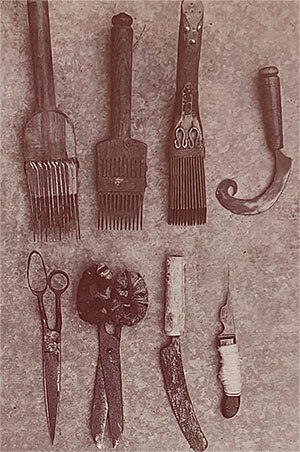

A minimum set of tools is required to make an oriental carpet. The yarns are usually cut with a knife and the knotted rows are tightly fitted to the previous ones. The height of the knots is regulated with scissors after a row is completed, but this is not the final thickness of the carpet. In some carpet manufacturing areas, the height of the knots is gradually adjusted during the production process, but usually a thorough finishing operation is carried out when the carpet is removed from the loom. In some regions, carpet weavers use a hook-like tool with one end sharpened to a knife-like edge to make symmetrical knots more quickly. In other regions, a small sickle-shaped knife is used, sharpened externally. According to a study, similar tools have been found in Bronze Age archaeological sites in Turkmenistan.

Various objects with a serrated design are used to compress weft yarns and knots. With these tools, knots are placed between the warp threads and then pressed tightly together. Some carpet-makers use a claw tool, which is placed between the warp threads and compressed with a hammer by means of strong blows. The result is a carpet that is noticeably stiffer to the touch. In some areas, a sickle-shaped, serrated iron tool is used to compress the knots. The tools used in modern workshops are very similar to those used by nomadic carpet makers, and sometimes local variations are found. In general, however, conclusions can be drawn about the origin of a tool. The tools used for percussion may be made of wood or metal.

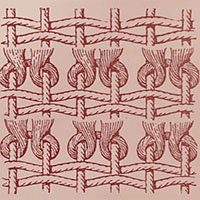

The value of handmade carpets is determined by the number of knots, in addition to age, pattern and material. Three main types of knotting are distinguished for hand-made carpets.

The Persian knot Senneh

The Persian knot is asymmetrical and open on one side, leaving fewer gaps and less bulky than Turkish knots. Persian knots are most often used for intricate patterns and floral designs. A much denser knotted carpet can be made in this way. Iran, Pakistan, India, Nepal, Tibet and China typically use Senneh knots.

The Turkish knot Ghiordes knot

The Turkish knot is symmetrical, leaving two small bumps on the back of the carpet inside each knot - it ends up looking like a double knot. The knots in the carpet will be much stronger. Afghanistan, Turkey, Armenia, Azerbaijan and Northern Iran prefer to use this type of knot.

The Jufti knot

The Jufti knot, or false knot, is tied around four strands instead of two, creating a short cut. When using a Jufti knot, the weaver spends less time on the carpet, resulting in faster processing time and lower value and quality.

Caring for handmade carpets

Handmade carpets, like all carpets, should be moved occasionally. Occasionally rotate your Oriental carpet to increase the life of its beautiful heritage. This will keep the wear on the carpet even, especially if one area gets more sunlight or traffic than the other corners. handmade carpet will initially be prone to shedding of its wool, but after the first few weeks the shedding will diminish and eventually disappear completely. Want to read more about cleaning oriental carpet?

How to choose the right oriental carpet.

When buying a new carpet, make sure you choose a handmade carpet that is large enough to fit in your room. If you choose a carpet that is too small, the room will look smaller and the decor will look out of place. If you choose a carpet that is too large and, say, part of the carpet goes under the furniture, it's a waste of money and, if the furniture is heavy or has a thin base, it could damage your handmade carpet. Be sure to measure the room before ordering a new carpet. You may want to measure a minimum and maximum size. If the seating set is light in colour then you may want to choose a darker carpet to accentuate both the furniture and the carpet. If you choose the same level as the furniture, the room will look dull and monotonous. Of course, the carpet should include colours that dominate the room. Take a look around our carpet shop and find the one that best suits your room! Want to know exactly how to recognise a handmade carpet?

Without a doubt, handmade carpets are the most valuable.

Below, we will show you exactly why this is the case, and how handmade carpets are made in their original home country today!

The first step in making handmade carpets is usually done by women, which involves washing and carding the wool. This is then spun into yarn by a wooden frame. The next step is to dye the yarn to the desired colour, usually using natural dyes. After drying, the hand-knotting of the carpets can begin and is carried out by trained carpet weaving specialists. The more fortunate can work at a loom, but many do their work squatting on the floor. When the oriental carpet is finished, it is sheared and than washed four times, then shaved to ensure an even surface. It is then washed once more, the fringes are made, and only after these processes is the handmade oriental carpet considered finished.